In construction, choosing a building’s structural system is a critical decision. Indeed, this foundational choice dictates nearly every step of a project. It profoundly influences timelines, budgets, and long-term performance. For generations, the debate centered on reinforced concrete versus hot-rolled structural steel. However, a third contender has now entered the ring: Light Steel Framing (LSF).

Consequently, the rise of LSF shifts the conversation from materials to methodology. Is it better to pour on-site, weld beams, or assemble a precision-made frame? Answering this requires looking beyond old habits. This guide offers a rigorous comparison for architects, engineers, and developers. Specifically, we will compare LSF, reinforced concrete, and hot-rolled steel across key metrics. Our goal is not to declare one winner. Instead, we aim to provide the knowledge you need to select the ideal system for your project.

A Brief on the Contenders

First, let’s briefly review the fundamentals of each system.

1. Reinforced Concrete

This is a composite material built on-site. Specifically, concrete combines the compressive strength of cement with the tensile strength of steel rebar. The process involves building formwork, placing steel, and then pouring the concrete. Afterward, workers must wait for it to cure. For decades, it has been the benchmark for permanent structures with high thermal mass.

2. Hot-Rolled Structural Steel

Architects use hot-rolled steel for skyscrapers and vast, column-free spaces. For instance, these are ideal for stadiums or aircraft hangars. Factories form massive I-beams and trusses at extremely high temperatures to provide immense tensile strength. Then, crews lift, bolt, and weld these heavy components together on-site. Therefore, it is the top choice for large-scale, high-rise construction.

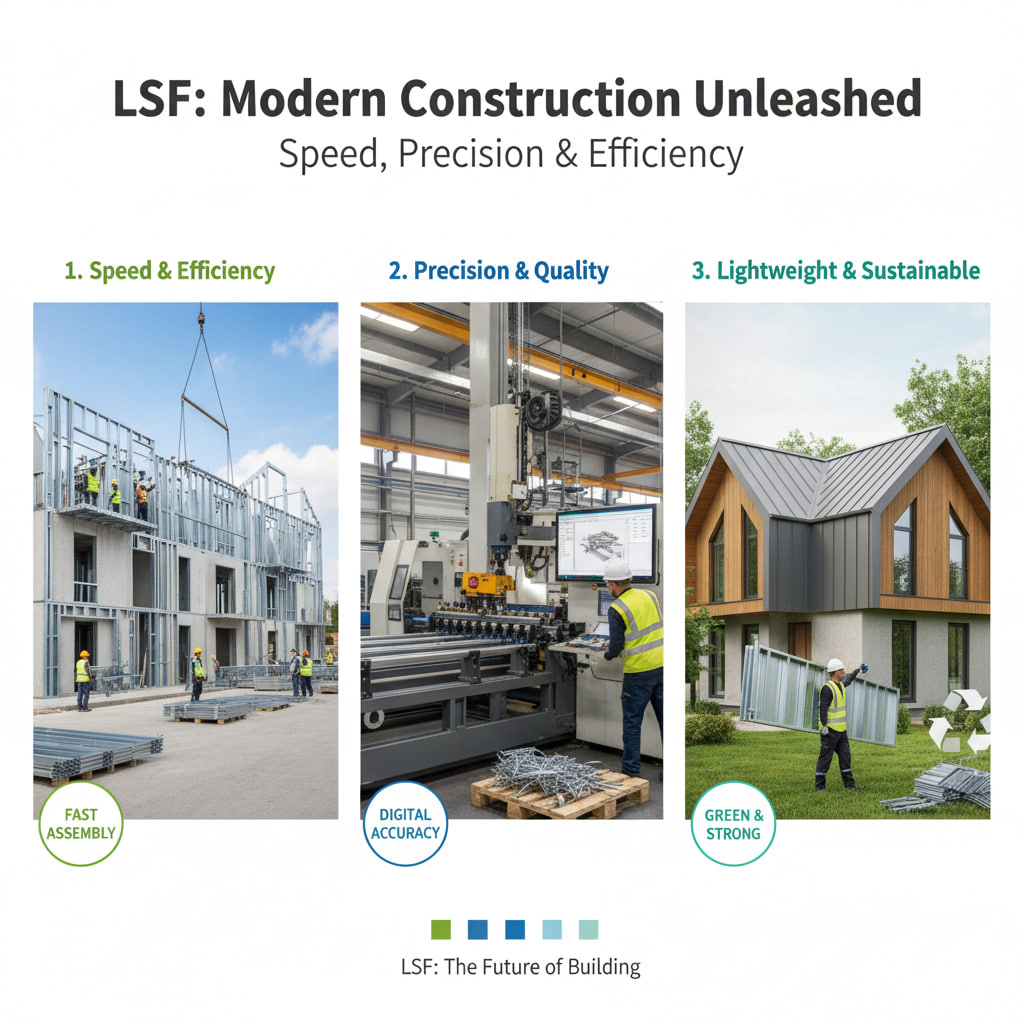

3. Light Steel Framing (LSF)

LSF, also known as cold-formed steel, represents a move toward intelligent manufacturing. It uses lightweight, high-strength steel sections. Machines precisely shape these sections from coils at room temperature. Furthermore, engineers digitally design the components. Factories often pre-assemble them into panels. Overall, the system emphasizes precision and speed, arriving on-site ready for rapid assembly.

The Head-to-Head Analysis

A system’s true value emerges under real-world project pressures. Let’s analyze how these three systems perform.

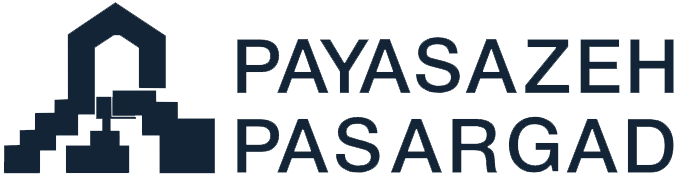

1. Speed of Construction & Project Timeline

Speed is where the differences are most clear.

- LSF: The LSF method is built for speed. Specifically, its greatest advantage is running processes in parallel. While crews prepare the foundation on-site, a factory simultaneously manufactures the superstructure. This off-site production is also immune to weather delays. On-site erection is a fast assembly process, not fabrication. In fact, a skilled crew can assemble a house frame in days. There is no curing time.

- Reinforced Concrete: In contrast, this is a slow, linear process. Each step must follow the last one. For example, workers build formwork, tie rebar, and pour concrete. Then, they must wait for it to cure. Curing alone can add weeks and significant downtime to the schedule. Moreover, the entire process is highly susceptible to weather delays.

- Hot-Rolled Steel: This method is faster than concrete. However, it is still a labor-intensive on-site process. It requires extensive crane time to lift heavy beams. Additionally, skilled labor must bolt and weld them, which is expensive.

- Verdict: For low-to-mid-rise projects, LSF holds a commanding speed advantage. Conversely, concrete is the slowest. Hot-rolled steel falls in the middle.

2. Structural Weight, Foundations, and Logistics

A structure’s dead load affects the entire project.

- LSF: LSF is exceptionally lightweight. In fact, it has the highest strength-to-weight ratio. An LSF structure can be 70% lighter than a concrete one. This results in smaller, shallower, and cheaper foundations. It requires less excavation and concrete, saving time and money. Logistically, smaller trucks can transport components. Crews can handle them with light machinery, simplifying work on tight sites.

- Reinforced Concrete: By far, this is the heaviest system. Its immense weight demands massive and deep foundations. Consequently, these foundations are costly and time-consuming to build. The logistics are also demanding. They require a steady flow of concrete trucks and large pumps.

- Hot-Rolled Steel: This system is lighter than concrete. However, it is still a heavyweight system. Its large columns demand robust foundations. Furthermore, the heavy beams require large cranes and careful logistical planning.

- Verdict: LSF is the clear winner here. Its light weight creates a ripple effect of savings. Therefore, it is ideal for projects on poor soil or for building extensions.

3. Precision, Quality Control, and Waste

A building’s quality ties directly to its structural precision.

- LSF: This system uses a “digital-to-physical” model. Specifically, CAD designs go directly to manufacturing machines. This results in components with sub-millimeter accuracy. Thus, the factory-controlled process eliminates on-site inconsistencies. The result is straight walls and exact openings. Additionally, this simplifies the work for subsequent trades. On-site waste is nearly zero because every piece is pre-cut.

- Reinforced Concrete: In contrast, concrete is a “wet” trade susceptible to human error. For example, imperfect formwork or improper curing can cause defects. It also generates considerable waste from leftover concrete and formwork.

- Hot-Rolled Steel: Factories fabricate the steel members to high tolerances. However, final quality depends heavily on the on-site erection crew’s skill. The potential for on-site error is higher than with LSF.

- Verdict: LSF offers superior precision due to its digital manufacturing process. Ultimately, this leads to a better-finished building with less rework.

4. Cost Dynamics

Comparing costs requires looking beyond raw material prices.

- LSF: The raw material might cost more per ton. However, the total project cost is often much lower. This is because savings come from several areas. First, faster construction means lower labor bills. Second, foundations are cheaper. Third, you need less heavy equipment. Finally, finishing projects months earlier reduces financing costs. This has a massive impact on overall profitability.

- Reinforced Concrete: People often perceive concrete as cheap due to low material costs. However, its total installed cost is high. Huge labor needs and extended project timelines drive this cost up.

- Hot-Rolled Steel: Typically, this is the most expensive option. Both the material and the skilled labor for erection are costly. It is only cost-effective when its unique span capabilities are essential.

- Verdict: For its target projects, LSF is very cost-competitive. In fact, it often emerges as the most economical choice when analyzing total project cost.

5. Design Flexibility & Architectural Scope

Every material has its own architectural language.

- LSF: LSF is extremely versatile for most common buildings. For instance, it suits residential, commercial, and healthcare facilities. Its strength allows for large open-plan interiors. It is also adaptable to complex rooflines and curved walls. Furthermore, you can finish it with any type of cladding.

- Reinforced Concrete: Its main advantage is its plastic nature when wet. This allows architects to create fluid and sculptural forms. However, achieving these forms requires complex and expensive custom formwork.

- Hot-Rolled Steel: This material’s domain is scale. In other words, it is the only viable option for skyscrapers. It is also necessary for structures needing enormous, clear spans, like arenas.

- Verdict: There is no single winner. You must match the material to the architectural intent. Specifically, hot-rolled steel owns the mega-scale. Concrete excels at monolithic sculpture. Meanwhile, LSF offers the greatest versatility for most everyday projects.

6. Sustainability & Environmental Impact

A system’s environmental credentials are now paramount.

- LSF: Steel is the most recycled material on earth. Typically, LSF members contain high recycled content and are 100% recyclable. Additionally, the system’s low waste and light weight reduce transportation emissions. This makes it a strong environmental performer.

- Reinforced Concrete: Portland cement production is highly energy-intensive. In fact, it accounts for an estimated 8% of global CO2 emissions. Concrete is also heavy to transport and difficult to recycle.

- Hot-Rolled Steel: This material shares the high recyclability of LSF. However, it carries higher embodied energy from the hot-rolling process. Its greater weight also means a larger carbon footprint from transport.

- Verdict: LSF has a much better environmental profile than concrete. It also has a slight edge over hot-rolled steel due to its lower weight.

Making the Right Choice: A Project-Based Guide

So, how do you synthesize this information to make a decision?

You should strongly consider LSF for several project types. For instance, it is ideal for low-to-mid-rise structures. In addition, choose LSF when speed to market is a critical business driver. It is also the best choice if the project site has poor soil or tight constraints. Furthermore, you should use it for vertical extensions on existing buildings. Finally, LSF is perfect when high precision and low waste are top priorities. Conversely, reinforced concrete remains a viable choice in specific situations. For example, use it when the design requires extreme thermal mass. It also works well when the primary aesthetic is heavy or sculptural. Moreover, it can be a fit in regions with very cheap concrete labor.

Lastly, hot-rolled steel becomes necessary for certain demands. You must use it when building a high-rise structure. Similarly, it is essential when a design demands massive, column-free clear spans.

Conclusion

The choice between LSF, concrete, and steel is more than technical. Indeed, it is a choice of construction philosophy. Do you embrace on-site tradition, heavy-duty power, or precision manufacturing? Concrete and heavy steel have secure roles at the market’s extremes. However, the evidence for the middle ground of construction is overwhelming. For the homes, offices, and schools where most people live and work, LSF presents a superior value. Specifically, it answers the modern call for faster and more sustainable construction. Therefore, for the forward-thinking professional, identifying where LSF excels is essential for project success.