The construction industry, a titan of the global economy, has long struggled with a stubborn paradox. Despite its immense importance, it has consistently lagged behind other sectors in productivity. For decades, projects have been plagued by chronic budget overruns, frustrating schedule delays, and frequent disputes. A primary cause of this inefficiency stems from the industry’s reliance on traditional, fragmented methods for managing project costs. However, a digital revolution is reshaping this landscape. At its core is Building Information Modeling (BIM), and specifically its fifth dimension—5D BIM—which is fundamentally transforming cost estimation and budgeting.

This technology represents a paradigm shift, moving financial management from a reactive, error-prone accounting task to a proactive, data-driven project control system. By integrating cost data directly into a project’s 3D model, 5D BIM cost estimation offers a new era of accuracy, transparency, and efficiency for the Architecture, Engineering, and Construction (AEC) industry.

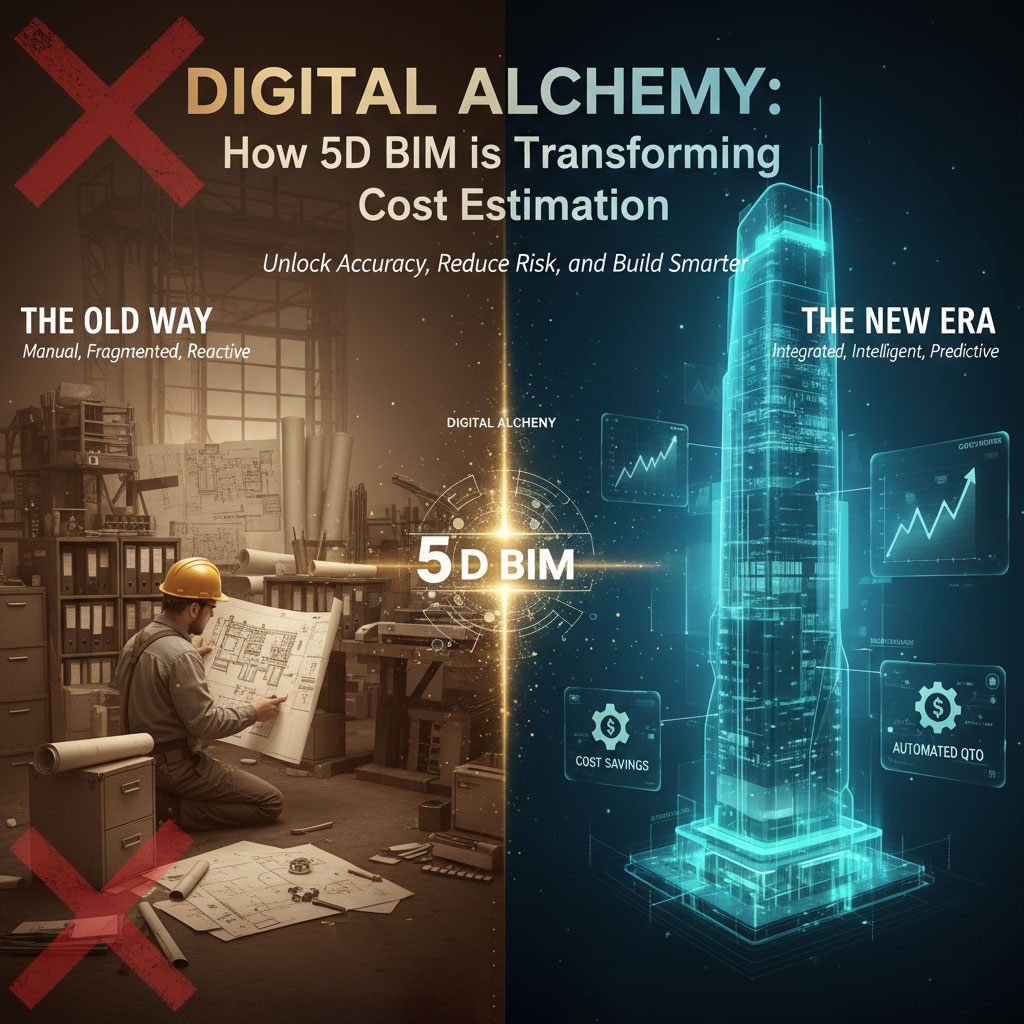

The Old Way vs. The New: A Fundamental Shift in Costing

To appreciate the impact of 5D BIM, it’s essential to first understand the limitations of the methods it’s replacing. The transition is not just an upgrade; it’s a complete redefinition of how financial data is generated, managed, and used throughout a project’s lifecycle.

The Pitfalls of Traditional Cost Estimation

For years, cost estimation has been a manual, linear, and fragmented process. Estimators would painstakingly review stacks of 2D drawings, manually measuring and counting every element to calculate the required materials and labor. This method, known as manual quantity take-off (QTO), is incredibly labor-intensive and highly susceptible to human error. A simple misinterpretation of a drawing or a calculation mistake could throw a budget off by a significant margin.

Furthermore, this workflow created information silos. Costing was typically performed late in the design phase, making it a retrospective exercise rather than an integral part of decision-making. When design changes inevitably occurred, estimators had to repeat the entire laborious process, increasing the risk of errors and inconsistencies. This disconnect between design, schedule, and cost often led to inaccurate forecasts, financial disputes, and legal claims.

Enter 5D BIM: A Smarter Approach to Cost Estimation

In sharp contrast, 5D BIM cost estimation leverages a centralized digital model to create an integrated and dynamic approach. Instead of manual measurements, quantities are automatically extracted from intelligent 3D objects within the BIM model. For instance, the volume of concrete in a beam or the surface area of a wall is an inherent property of the model and can be queried instantly. This automation drastically speeds up the QTO process while ensuring a much higher degree of accuracy, as all data comes from a single, coordinated source.

Crucially, the data flow is bi-directional. Cost information is dynamically linked to the model. Therefore, when an architect changes a design element—like altering the type of window used throughout a building—the associated quantities update automatically. This change instantly reflects in the linked cost estimate, providing the entire team with real-time financial feedback. This integration transforms cost into a key design parameter from the very beginning, enabling continuous monitoring and control.

How Does 5D BIM Cost Estimation Actually Work?

Implementing 5D BIM involves more than just new software; it requires a structured framework that governs how data is created, linked, and shared. Several key components make this powerful process possible.

Automated Quantity Take-off (QTO)

The foundation of the 5D framework is the automated QTO. A BIM model is composed of intelligent objects packed with data. These objects possess inherent properties like dimensions, volume, and material specifications. As a result, the system can extract the precise quantities needed for cost estimation directly and automatically. The accuracy of this process depends heavily on the model’s Level of Development (LOD), which specifies how much detail an element contains at each project stage.

Linking Model Elements to Cost Data

The “fifth dimension” comes from creating a dynamic link between the extracted quantities and a cost database. The most sophisticated workflow involves linking the BIM model to a specialized 5D cost management platform (like Vico Office or CostX). These platforms contain extensive cost libraries and maintain a live link to the model. Consequently, any modification to the design automatically triggers an update in the cost plan, offering a robust and dynamic solution for budgeting.

Real-Time Simulation and Scenario Analysis

This integrated framework enables powerful “what-if” scenario analysis. By linking the 3D model (geometry), 4D schedule (time), and 5D cost plan (money), stakeholders can instantly visualize the financial implications of any design change. For example, an architect can model two different façade systems, and the 5D system can immediately provide a detailed comparative cost analysis. This empowers the team to make informed decisions that balance design, function, and budget from the project’s inception.

The Real-World Benefits of 5D BIM Cost Estimation

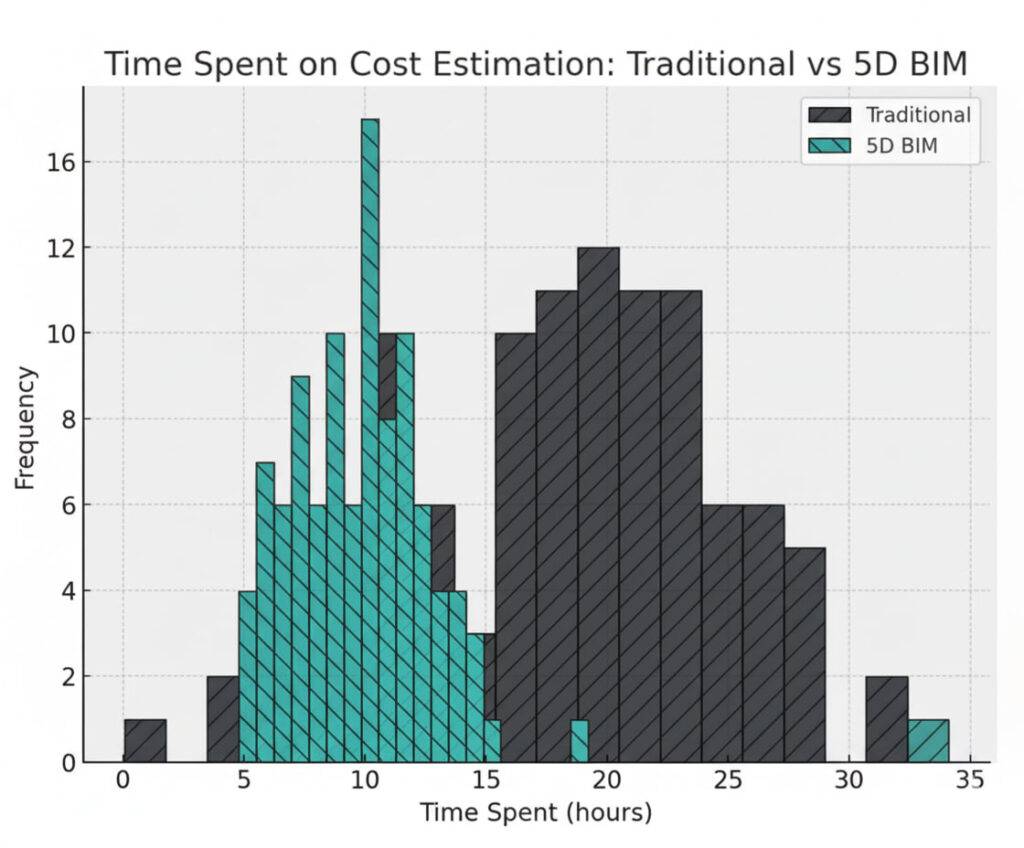

The theoretical advantages are compelling, but the true value of 5D BIM is proven by its measurable impact on project outcomes. A growing body of research provides clear evidence of significant, quantifiable improvements.

Unprecedented Accuracy and Reliability

By eliminating manual calculations, 5D BIM drastically reduces human error. Studies have shown that BIM-based estimates are not only faster but also a more accurate reflection of the true project cost. This leads to better budget alignment and far fewer financial surprises during construction, fostering greater trust between clients and contractors.

Dynamic Budgeting and Proactive Control

Perhaps the most transformative impact is the shift from static budgets to dynamic cost control. The live link between the model and the cost plan allows teams to monitor expenses in real-time. Project managers can identify potential overruns at the earliest possible stage and take corrective action before they escalate. This proactive approach is a world away from traditional methods, where budget deviations are often discovered only after it’s too late.

Massive Reductions in Risk and Rework

A huge portion of cost overruns comes from rework caused by design errors and clashes between building systems (e.g., a pipe running through a structural beam). BIM’s 3D visualization and automated clash detection allow teams to find and resolve these issues in the digital model before construction begins. The results are substantial, with case studies reporting:

- 40-50% reduction in rework costs.

- 30-60% fewer design errors.

- Up to an 80% reduction in the time required to generate an estimate.

Ultimately, these benefits lead to better overall project performance. Data shows that 5D BIM cost estimation can contribute to an average reduction in total project costs of 15% and a 20% reduction in project timelines.

Why Isn’t Everyone Using 5D BIM? The Barriers to Adoption

Despite the clear benefits, widespread adoption of 5D BIM remains inconsistent. The path to implementation is filled with significant challenges that are technological, organizational, and cultural.

- Technological Hurdles: A lack of universal software standards creates interoperability issues, meaning data can be lost or corrupted when moving between platforms. Additionally, the software itself can be complex and expensive, requiring high-performance hardware.

- Organizational Barriers: The high initial investment in software, hardware, and training is a major deterrent, especially for smaller firms. Furthermore, there is often strong cultural resistance to change from employees who are comfortable with traditional workflows.

- The Human Element: A significant skills gap exists in the industry. There is a shortage of professionals with the expertise to effectively implement a 5D BIM process. Many university programs have been slow to adapt their curricula, leaving graduates unprepared for the demands of a digitized industry.

- Legal and Contractual Issues: Traditional construction contracts were not designed for collaborative, model-based workflows. Unresolved questions about data ownership, intellectual property, and liability for errors in a shared model create uncertainty and risk.

These barriers reinforce each other, creating a cycle of inertia. Firms are hesitant to invest without client demand, but clients are wary of specifying a process that the industry may not be equipped to handle. Breaking this cycle requires a concerted effort from all stakeholders.

Conclusion

5D BIM is not the end goal; it is the foundation for the next generation of intelligent financial systems. Its future lies in its convergence with other disruptive technologies.

The structured data in a 5D model is perfect for Artificial Intelligence (AI), which will enable predictive cost modeling based on past projects. Blockchain and smart contracts promise to automate the payment process, triggering payments automatically once on-site progress is verified by IoT devices like drones or laser scanners. This would create a transparent, secure, and instantaneous payment system, eliminating disputes and administrative overhead. This convergence points toward a future of largely autonomous project financial management. The cycle of monitoring, valuation, and payment will become a seamless, automated loop. This is the ultimate paradigm shift that 5D BIM has set in motion—moving the industry from manual spreadsheets to a self-governing financial ecosystem that delivers projects with unparalleled efficiency and predictability.