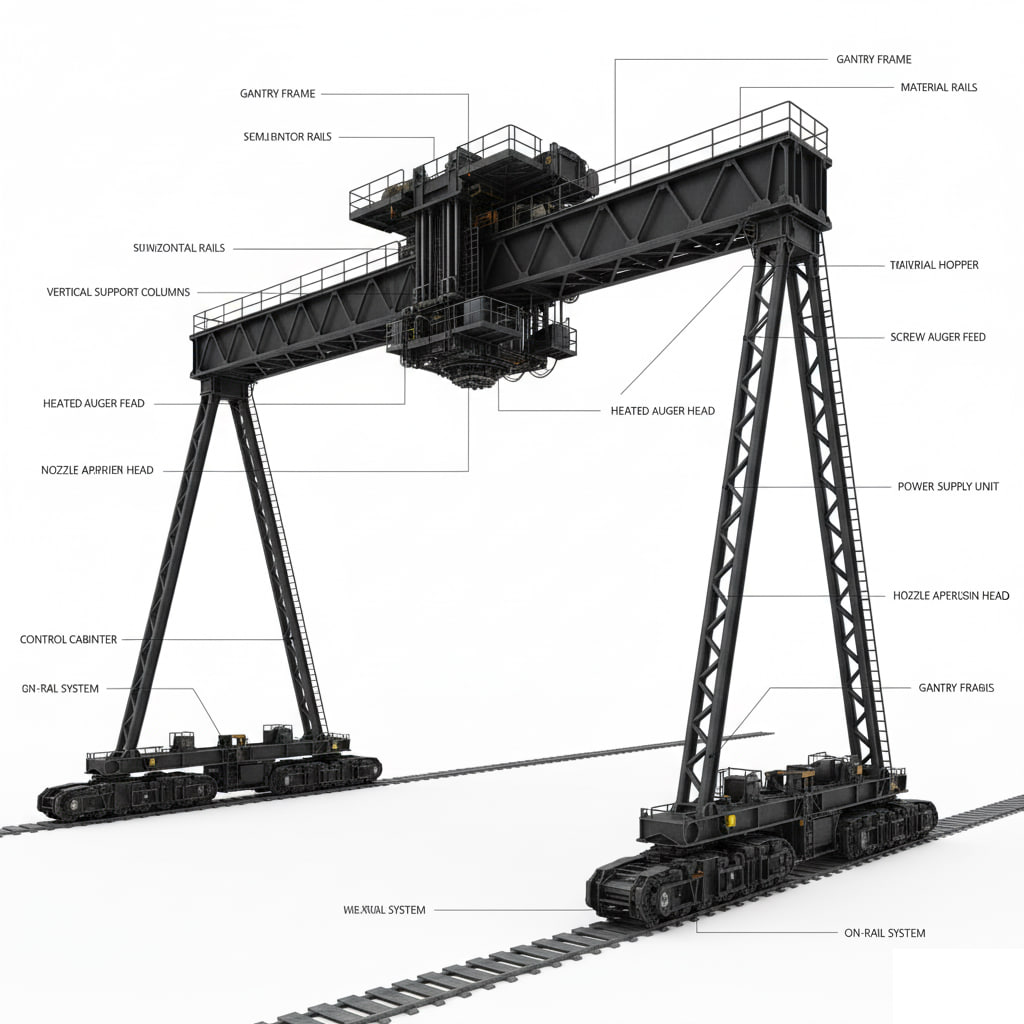

This series has explored the revolutionary potential of construction 3D printing. In addition, we have examined the practical process of building a house with this technology. The vision is compelling: a future where we can construct buildings faster, with less waste, and with greater architectural freedom. However, the path from a groundbreaking innovation to an industry standard is never simple. Indeed, this road presents both immense opportunities and significant obstacles.

For any construction professional, developer, or investor, a clear-eyed understanding of this duality is essential for strategic decision-making. The hype surrounding the technology is real, but so are the hurdles. Consequently, this article provides a balanced perspective on the current state and future of construction 3D printing. We will explore the value it can create and honestly assess the challenges that the industry must overcome for mainstream adoption.

Where 3D Printing Creates Unprecedented Value

The excitement for construction 3D printing stems from its potential to solve systemic problems. Moreover, it promises to unlock new market advantages. The opportunities, therefore, extend far beyond simply being a novel way to build.

Addressing the Housing Affordability Crisis

Perhaps the most profound opportunity is addressing the global housing crisis. In many countries, new home construction costs have spiraled out of reach for much of the population. 3D printing, however, directly addresses the primary cost drivers: labor and time. As a result, it offers a viable path to lowering the price of new housing. The combination of a faster schedule, a smaller workforce, and minimal waste can substantially reduce a home’s final cost. This is not just an incremental improvement; rather, it is a technological lever that could help developers and non-profits build affordable communities at a previously impossible scale.

A New Paradigm in Sustainable and Resilient Construction

Beyond cost, 3D printing presents a major opportunity to build better and more resilient structures. The sustainability benefits begin with waste reduction but do not end there. For instance, researchers are actively developing printable materials that use local earth or recycled waste. This work helps create a truly circular construction economy. In terms of resilience, the technology also excels. Monolithic concrete walls, printed as a single entity with steel reinforcement, have superior structural integrity. This quality makes them inherently more resistant to hurricanes, tornadoes, and earthquakes. Furthermore, the non-combustible nature of concrete provides a huge advantage in fire-prone regions.

Unlocking Mass Customization and Architectural Innovation

As noted, 3D printing liberates architects from the economic constraints of rectilinear design. The business opportunity, however, goes deeper than aesthetics; it enables “mass customization.” Imagine a housing development where every unit has a unique facade or a custom interior layout. With traditional methods, this would be an economic and logistical nightmare. With 3D printing, in contrast, it is simply a matter of loading a different digital file. This allows developers to offer a level of personalization that can be a powerful market differentiator. Consequently, it helps them move away from cookie-cutter designs to create more diverse and appealing communities.

The Real-World Challenges to Mainstream Adoption

Despite its promise, the widespread adoption of 3D printing is not yet guaranteed. The technology faces significant challenges that the industry is actively working to solve.

The Regulatory Labyrinth: Building Codes and Certification

The single greatest barrier to entry is the regulatory environment. Our building codes are prescriptive. Specifically, they are built around decades of experience with known materials and methods. These codes specify requirements like lumber dimensions or rebar spacing in a concrete wall. 3D printing, as a novel process, does not fit neatly into this framework. Getting a new system approved by hundreds of different building authorities is a slow and expensive process. Therefore, the lack of universal standards for testing and certifying printed structures remains a major bottleneck.

Material Science and Structural Reinforcement

While current printable concrete mixes are effective, the science is still evolving. Researchers are still gathering long-term performance data on metrics like creep, shrinkage, and durability. The most significant technical challenge, however, is reinforcement. Manually inserting rebar into the walls as they are printed is a functional but imperfect solution that slows the process. The “holy grail” for the industry is developing a fully automated reinforcement method. This could involve using high-strength fiber additives or a system that places steel concurrently with the concrete. Achieving this will be crucial for scaling the technology to build multi-story structures.

High Capital Cost and a Widening Skills Gap

Construction 3D printers are advanced robotic equipment. Consequently, they represent a significant upfront capital investment. This high cost of entry can be prohibitive for smaller construction companies. Beyond the financial investment, there is a human resource challenge. The industry already faces a shortage of skilled labor, and 3D printing requires a new skill set. Thus, there is a pressing need for technicians who understand robotics, digital modeling, and material science. This skills gap can only be closed by developing new vocational training programs.

Scalability and Integration with Traditional Trades

A 3D printer builds the walls, but a house is a complex system. A major challenge, therefore, lies in seamlessly integrating the printed shell with the rest of the construction process. The industry is still developing best practices for connecting roofing systems, flooring, and other components to printed walls. The workflows of plumbers, electricians, and HVAC technicians must also adapt. Currently, the interface between the high-tech printing phase and traditional finishing can be clunky. Streamlining this entire process is key to unlocking the technology’s full potential for speed and efficiency.

Conclusion

3D printing in construction is at a critical juncture. The opportunities are undeniably transformative, offering a path toward more affordable and sustainable buildings. At the same time, the challenges related to regulation, materials, cost, and workforce are formidable and real.

Therefore, 3D printing is not a magic bullet that will instantly replace all other construction forms. Rather, it is a powerful new tool. For the foreseeable future, it will excel in specific applications where its strengths align perfectly with project needs. The path forward will be one of incremental adoption. This progress will be driven by collaboration between innovative firms, tech companies, materials scientists, and forward-thinking regulators.

For leaders in the construction industry, the takeaway is clear. The future does not belong to the uncritical evangelist or the dismissive skeptic. Instead, it belongs to the informed realist who understands both the opportunities and the challenges. Engaging with this technology today is no longer about exploring a novelty; it is about preparing for the inevitable evolution of our industry.